Consider Fourslide for Light-Gauge Metal Stampings

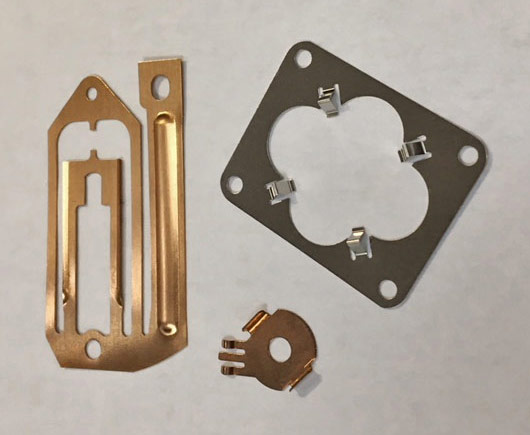

Many manufacturers have long employed the fourslide process to produce formed parts with multiple bends and forms. Fewer, however, consider the fourslide process when faced with flatter parts, such as those pictured here.

These types of light-gauge metal stampings are produced entirely within the die set on the fourslide machine – no need to utilize the slide forming area. But, because of the low price of the fourslide tooling, this approach is far more economical than making these parts on a power press.

When you’re faced with the need to produce a light weight stamping, think of Fourslide first. We just might be the best solution. Contact us to request a quote or discuss your part.