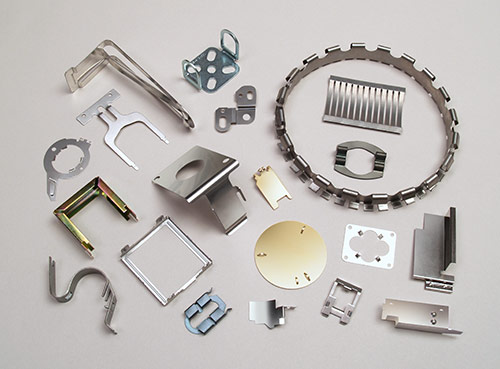

Is my part a Fourslide part?

We get this question every day as manufacturers struggle with ballooning lead times, expensive changes to tooling, and quality control for critical components. And the answer may surprise you!

Sophisticated high-volume parts that traditionally required complex tooling on a progressive power press can be an excellent fit for the fourslide manufacturing process. With its unique integration of stamping and forming operations, the fourslide process can dramatically reduce typical tooling costs, halve tooling lead times, and eliminate post-production adjustments needed to meet specifications.

From precision metal stampings, flat springs, wire, and ribbon forms to complex forms with multiple bends – whatever its name – if your part is stamped or formed, less than 2″ wide, and less than 0.075″ thick, it may be a fourslide part.