Considerations for Prototyping Metal Parts

Here at Fourslide, we have long offered prototyping services for our customers. A very high percentage of the jobs we quote are for flat springs, contacts, clips, and other metal parts that have never been previously made, to be used in brand-new devices and products. We pride ourselves on helping customers make informed decisions about part design that save them both time and money.

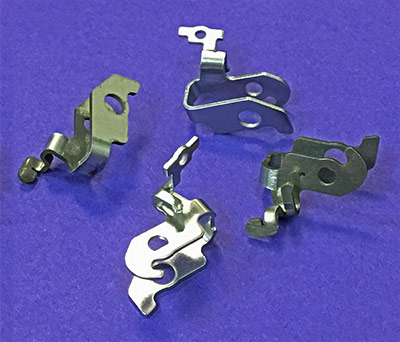

Prototyping is invaluable in determining whether or not our customers’ designs actually work for fit, form and function. When determining final feature geometry, complex parts like the one shown here benefit greatly from this process. It amounts to inexpensive insurance; for reassurance prior to making the investment in production tooling. It is foolish to scrimp on prototyping cost.

In order for your prototypes to have value, they must be a faithful representation of the part as it will actually be created in production. It is completely counterproductive to fashion prototypes that are not achievable in the production process. Factors such as bend radii, spring back and grain direction must be accounted for, keeping in mind what is achievable in production. For these reasons, it is most prudent to have Fourslide provide your prototypes, as well as your production requirements.

Prototyping often prompts the customer to modify design, improving the performance of the part. It is a crucial step in product development, helping to ensure the success of your project. Contact us to discuss your project and how prototyping could save you from major headaches once you enter production.