Anticipating Problems in Bulk Metal Parts Manufacturing

A very high percentage of the parts for which we receive requests for quotation have never been made before. Whether it’s a flat spring, a battery contact, a wire form or a spring clip, our customers are usually fully immersed in designing a part that will fit their product and function as required. The manufacturability of their part often takes a back seat, but this is our primary concern when reviewing a new design.

The most commonly considered factors for manufacturability include the tightness of bend radii, grain direction of the material, material temper, sufficient clearance for over-bending, and the distortion resulting from the heat treat process.

One particularly insidious potential problem that often goes overlooked is part tangling and nesting. High-volume parts are necessarily manufactured in bulk processes, in order to produce them economically. Many parts will go through several operations, from stamping, forming and washing to heat treating, deburring, and plating. The more steps that are required for processing of a part, the more opportunities there are for parts to tangle – resulting in incomplete plating coverage and costly sorting and untangling.

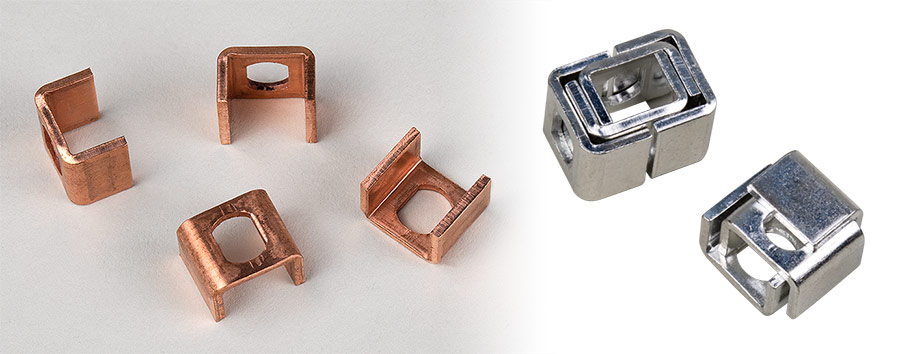

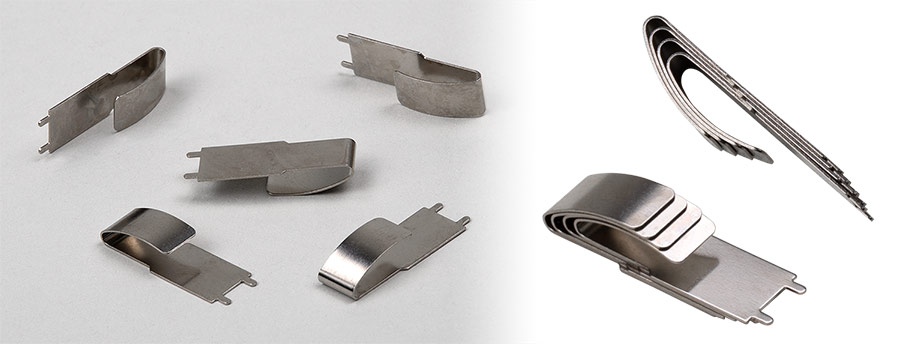

It is often easy to spot potential tanglers during manufacturability reviews and make changes to avoid the problem altogether. Other times, however, it’s nearly impossible to envision how two (or sometimes three or four) parts will join together – and stay together. The photos below show example of parts separated, looking quite innocent. As you can see, these parts actually joined together quite efficiently.

Often, there are relatively simple solutions to these problems. Closing a gap or a seam so that parts cannot interlock is one. Opening a gap or seam so that parts can fall apart, rather than stay joined, is another. Adding a feature that interferes with the parts tangling often works. Increasing the length of the parts’ sides by only .010” worked for the parts in the first example below, making it physically impossible for them to fit together.

When designing a new part, ask yourself if your parts will remain separate throughout bulk processing. If you’d like more experienced eyes to review your design, we’re glad to be of assistance.